TPET intelligent factory platform

TPET intelligent factory platform is a total solution of both software and hardware providing manufacture information, automation and intelligence. Through integrating automatic transport,automatic manufacture equipment,automatic testing equipment and information software, the platform realizes data collection,process monitoring,TPM equipment management,quality management,production scheduling and data analysis in the production,hereby the intelligent manufacturing management of information,intelligence and flexibility in all work sites.

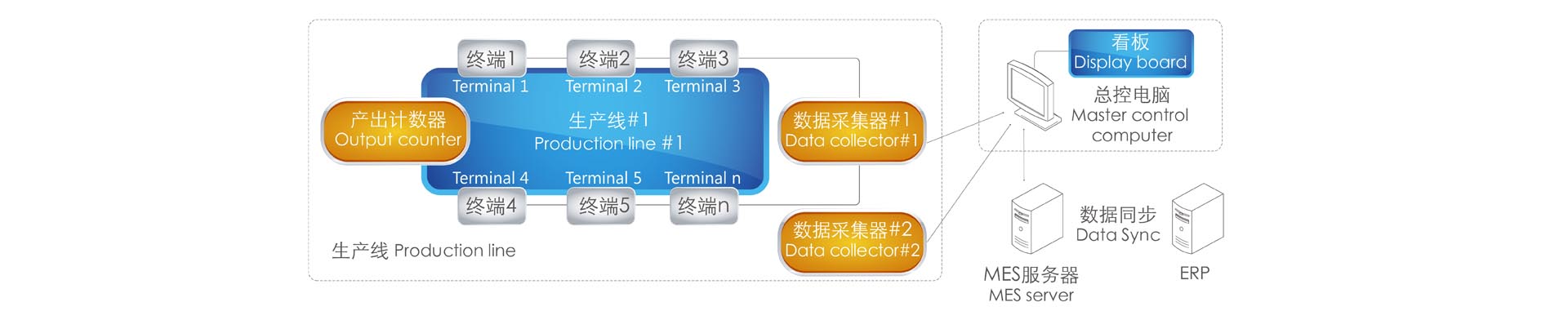

Spv data acquisition system

The system can offer efficient automatic data collection system to customers in manufacturing industry. The data to be collected includes all quality data types on site, output information, equipment parameters, etc. At the same time, the system realize automatic data collection through all kinds of ports and sensors.

Advantages and characteristics

Automatic collection and in-time monitoring.

Prewarning at any moment and automatic analysis.

Obtain present status on equipment and production task and operation.

Check and receive the information from database at any time.

Transmit and check the name and quantity of defective products at each station.

Automatically judge the measurement result.

Statistics analysis system

The statistical analysis system is one which classifies the data of manufacturing process for sorting treatment. The collector send the data that has been collected to cloud data center, then the system reads the system reads the information from cloud data center, classifies and then treats them, to provide reliable basis for enterprise manufacturing

Advantages and characteristics

Sorting treatment and automatic analysis of collected data.

Comprehensive statistics data and very detailed analysis.

Coordinated with other systems, thus lower rate of error.

Helpful to making the production schedule.

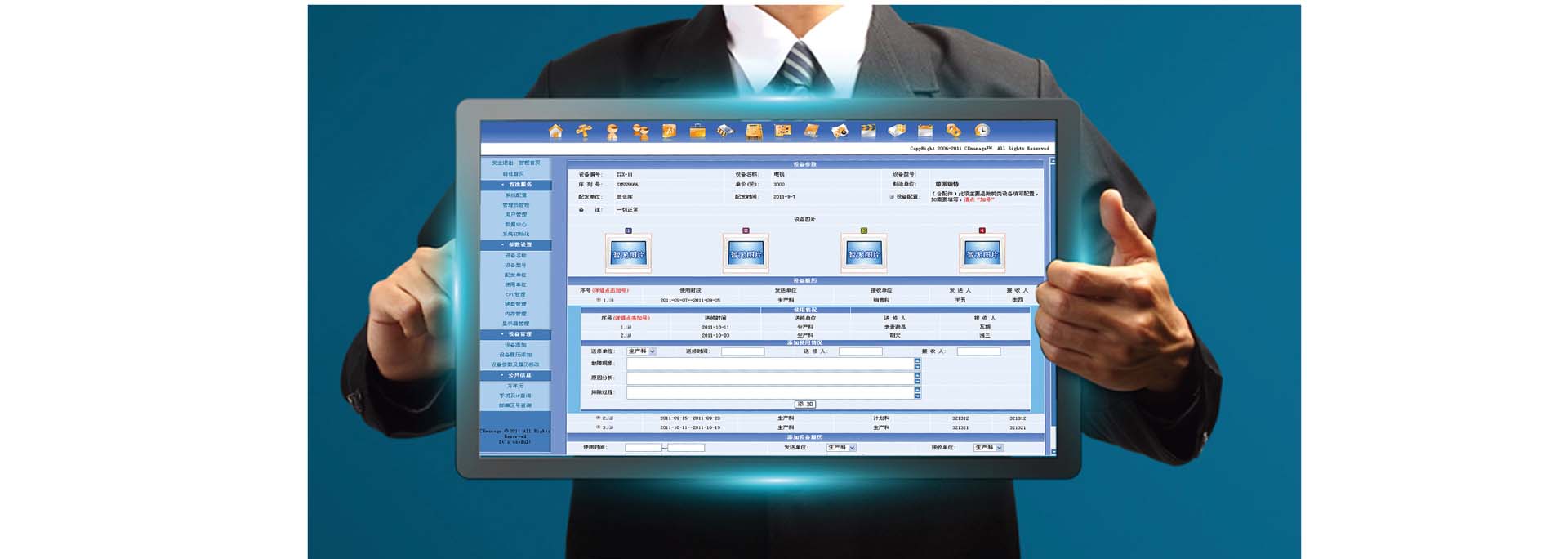

Equipment management system

The equipment management system is to control the production, maintenance of the equipment in workshops. With the information that has been collected, the system monitors the equipment operating in real time, sends prewarning against equipment failures in order to maintain them in time. Besides,it produces daily maintenance schedule, machine use rate with data to reduce the time for equipment stop and maintenance cost, to improve equipment lifespan management, to visualize and improve equipment efficiency and productivity

Advantages and characteristics

Automatic prewarning function, can produce automatically the equipment failure, maintenance schedule and repair.

Add equipment file management system, improve workshop equipment file.

Can analyze the equipment info systematically.

Know about the equipment running cycle and carry out the maintenance schedule.

MANUFACTURING EXECUTION SYSTEM

TP-MES is a manufacturing information management system for executives of manufacturing enterprises workshops. Based on such problems as complex technological process, vast pool of data, difficult production coordination, the system adopts up-to-date software,hardware and network technology, builds an effective solution to guide workshop manufacturing.

Advantages and characteristics

Find abnormal Information automatically.

Fine management of manufacturing process.

Reduce the cost of work-in-process.

Improve visibility of field events.

Collect data in real time and grasp production progress;

Automatically scheduling and adjust the priority flexibly;

Improve delivery accuracy and reduce the time for production output;

Achieve real time information to make scheduling more effective;

Feedback quality problems in time, fallow up quality inspection records and improve product quality,

Reduce artificial statistics and handwork reports, improve capacity of management staff on site.

PIECEWORK WAGE SYSTEM

Piecework wage system counts up and analyzes personal salary based on personal output data within a certain period according to the procedure of each employee, and connects with attendance records. The exeucution of piecework wage will help improve the level of enterprise management

Advantages and characteristics

Count up the piecework wage of an individual or a department within any period.

Set up many basic parameters, inducing quota man-hour, piecework price.

Working procedure can be input according to job No,work position and by batch, count piecework by an individual or a group.

Can set up management process,labor cost flexibly and connect them with different employees' output that has been finished practically and the quality conditions.

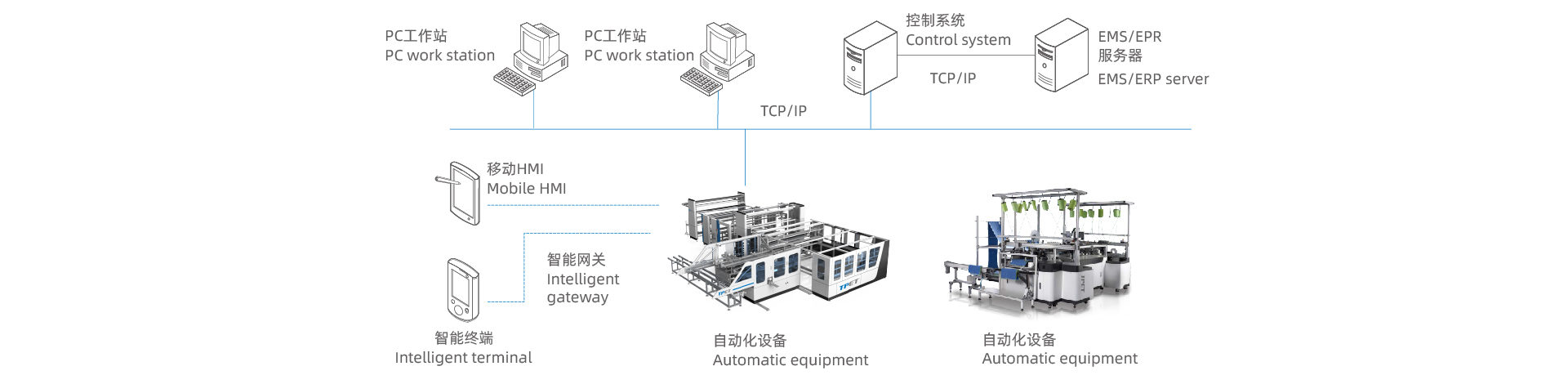

MANUFACTURING MONITORING SYSTEM

Through on-site PC terminal, electronic display board, mobile terminal, the system shows the running status of the production line and each section; shows information on processing manufacture, quality, equipment and material supply; prompts ail abnormal information; displays high-definition video on site. The system realize transparent management of work site through various visual tools.

Advantages and characteristics

Facilitate monitoring and supervision.

Help investigation and make responsibility dear.

Improve efficiency of enterprise management.

Improve management and supervision effect.

Display and supervise manufacturing status in real time.

Visualized instruction sending and operational guidance.

PRE-WARNING SYSTEM

The equipment including the sensor collect data and send it to cloud data center. Through analysis about intelligent manufacturing system, monitor all kinds of abnormal information automatically, send abnormal status information to the warning tool (such as, mobile message and Email) in time and inform the person related.

Advantages and characteristics

Inform layer by layer, to ensure that everybody gets the information;

Classi1ying alarm, to handle with the related failures targeted;

Many ways of alarm, to improve the concern about the problem

Deduct the time for checking up failure, to improve the efficiency to solve problems.

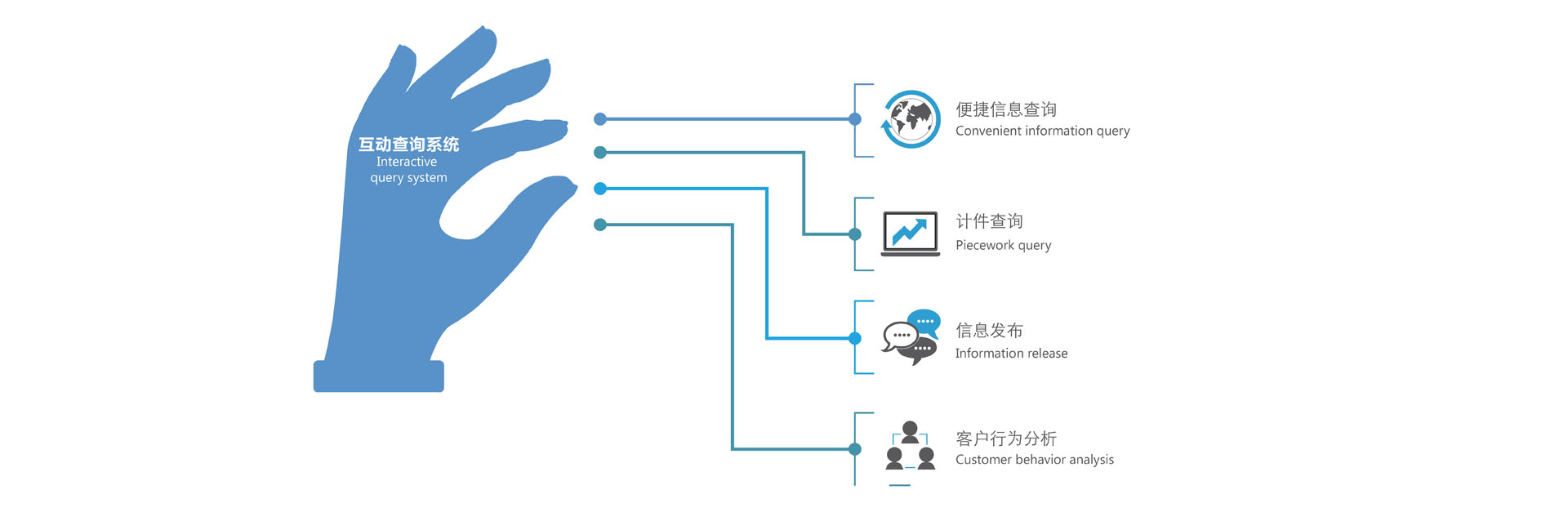

MANUFACTURING MONITORING SYSTEM

TP-MES Interactive query system provides various functions of enquiry, can analyze workshop data from different perspectives. People can inquire product manual, manufacture schedule, order executing progress, material status, quality condition and piece-work wages, etc

Advantages and characteristics

Convenient information enquiry, support fuzzy inquiry by keywords.

Strong information publishing(urgent information, news,etc. can be published at any time).

Customer behavior analysis, including product request potential customer mining.

Employees can inquire his/her piecework wage in real time.

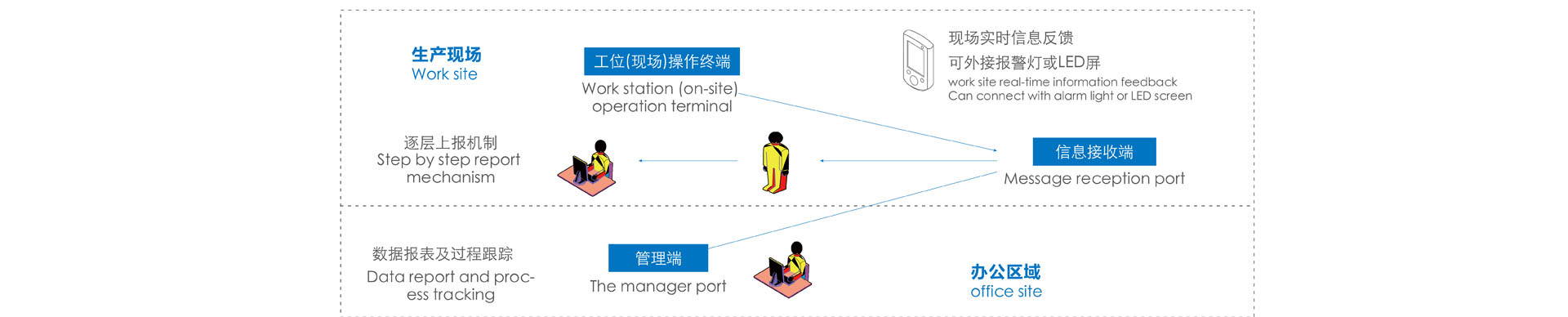

ANDON CALLING SYSTEM

With the equipment such as sensor, the system collects information and send it to cloud data center. Through analysis by intelligent manufacturing system, the system monitor different kinds of abnormal information, send the abnormal status data to the alarming tool (such as, mobile message and Email) and inform the personnel related in time.

Advantages and characteristics

Add many pre-warning nodes, realize whole-process control from the beginning to the end. When reaching pre-warning value, the system send pre-warning information automatically.

Provide many ways of alarming, including warning light, prompting display board, short message and broadcast etc.

Set up pre-warning handling mechanism,standardize ways of handling pre-warning, such as warning status 1, handle with the failure according to corresponding emergency plan.

Report abnormal problems on production lines, such as quality problems, equipment failure,material shortage and safety problem, through the site terminal. The system can inform orientedly the personnel related to handle them in the form of short message, PC message,etc. If no response, the system will report to the higher authority, that is, to notify layer by layer.

exception handling: the personnel related should be on the spot and handle with abnormal events at notice, sign up on the system, in the form of inputing account No. or swipe IC card. After treatment, the system will send out the information of' the problem has been solved'.

PDP INTELLIGENT DISPATCH SYSTEM

The system is developed according to specific context of use in factories, with advanced PDP intelligent dispatch control algorithm. It can realize the management of PDP car,traffic,dispatching,equipment running,production task,communication and automatic charging. The system can be connected to MES system, production line system, etc to build up flexible and up-to-date intelligent logistics system.

Advantages and characteristics

Safety-the vehicle routing of people driving is not known well, but the guiding route of PDP is very dear, which is more safe.

Predictable- AGV can stop automatically when running into an obstacle on the route.

Improve logistics management-intelligent control inside PDP system can help keep goods in better order, thus the workshop more tidy and neat.

Flexibility-allow to change routing schedule to the maximum.

Dispatching capacity-due to its stability, AGV system has optimized dispatching capability.

Site requirement-PDP requires much narrower roadway than traditional forklift. The flexibly running PDP can also load and discharge goods from conveyor belt and other mobile equipment